The American startup Aircela has unveiled the first compact system for localized production of synthetic gasoline made from water and by capturing carbon dioxide from the air. Costs and energy efficiency, however, remain highly debatable

From the rooftop of a building in the middle of Manhattan, New York, Aircela’s managers officially presented to the world the first compact system for producing synthetic gasoline. The announcement, however, seems to have been less than fully clear, as several major news outlets rushed to call it a miracle device capable of “turning air into gasoline.” In reality, the system presented by Aircela is yet another example of how enthusiasm for green technologies can sometimes overshadow engineering rationality.

It is true that the system uses almost exclusively air and water as its base elements to obtain “green” gasoline. But as physics teaches us, energy cannot be created from nothing, and any transformation inevitably involves losses that reduce the final efficiency. In this case, the problem is sidestepped by relying on electricity from the grid to first produce hydrogen and then gasoline—at a rate of about one gallon per day, just under four liters.

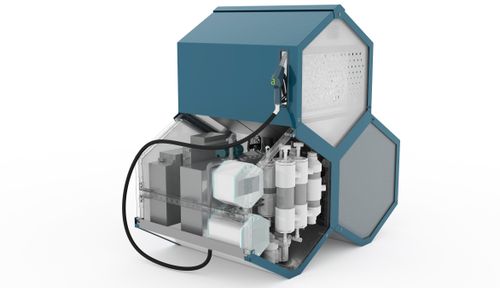

Roughly the size of a refrigerator, the system also claims to remove up to ten kilograms of carbon dioxide from the air. However, the energy input required for electrolysis and synthesis undermines its price/performance ratio unless the electricity comes from renewable sources. Not by chance, the same basic technology has been explored by leading industrial players such as Porsche, Siemens, and Prometheus Fuels—with little success, given that producing one liter of e-fuel can consume up to 50 kWh of electricity.

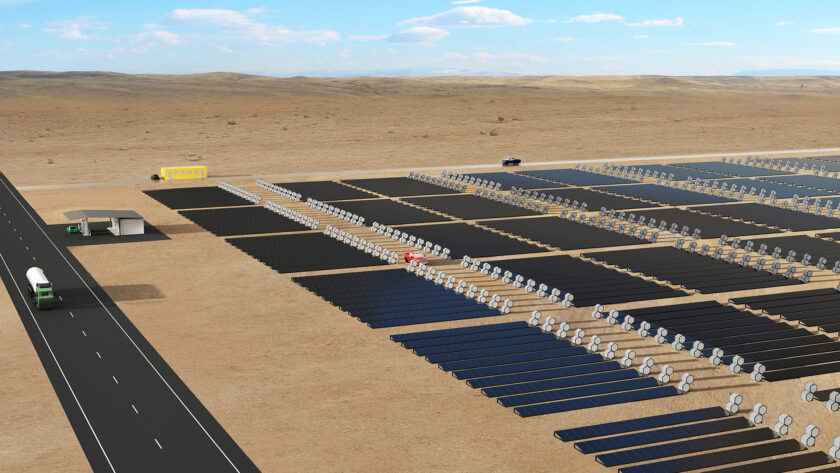

This means that synthesizing about four liters of gasoline could require as much as 160 kWh per day. To provide such an energy flow “for free” would require around 135 solar panels of 300 watts each, installed in a location with at least eight hours of strong sunlight per day. Under such conditions, each panel would generate on average about 1.5 kWh daily—a goal that is very difficult to achieve in most urban areas of Italy and many other regions.

Skepticism about the Aircela system grows further when considering that an electric car with a 50 kWh battery can travel about 300 kilometers, whereas with one liter of synthetic gasoline a comparable combustion-engine vehicle would barely cover 20 kilometers. It is clear, then, that the overall efficiency of the system is extremely low—far inferior to any electric drive that directly uses stored electricity, and even less efficient than using the hydrogen produced by the same system to power a combustion engine.

Technically, the Aircela process begins with capturing atmospheric CO₂ using an alkaline solvent, typically a potassium hydroxide solution, which traps the gas by turning it into dissolved carbonates. In parallel, water is split via electrolysis into hydrogen and oxygen, with hydrogen being critical for the next step. The captured CO₂ is combined with the hydrogen in a chemical reactor that, through hydrogenation, produces methanol. This methanol serves as a key intermediate, which can then be converted into a liquid hydrocarbon blend compatible with conventional combustion engines through a catalytic process known as “methanol-to-gasoline” (MTG).

The result is a synthetic gasoline free of sulfur and impurities, with an octane number similar to that of conventional gasoline. Thus, the system does represent an innovative approach to producing green fuels through CO₂ capture techniques. But like all emerging technologies, it faces major challenges in terms of energy efficiency, scalability, and above all costs—the real Achilles’ heel of a project that, according to Aircela, could bring units to market at about $5,000 apiece if built at scale, compared to today’s estimated $20,000 price tag.

Even if the target price were reached, it is hard to see how such a system could ever be cost-effective, and the price per liter of synthetic gasoline could never compete with fossil-based gasoline—unless free electricity were available. But in that case, it would be more efficient simply to feed that electricity directly into EV batteries.

In the end, Aircela’s technology remains more of a bold statement of intent than a viable solution, though the startup has already seen some positive returns from the project. It has in fact secured over $5 million in funding from Maersk Growth, the venture capital arm of Danish shipping giant A.P. Moller-Maersk, which is exploring the possibility of decarbonizing maritime transport through the use of synthetic fuels to power ships.